DIRD Felt Ltd

Introduction

DIRD Felt Ltd (ISO Certified) manufactures both polypropylene (PP) and polyethylene polyethylene terephthalate (PET) non-woven geotextiles. It serves both the domestic and international market with a daily production capacity of 85 tones of non-woven geotextile fabric and a stitching capacity of 130,000 geo-bags per day.

GEO-TEXTILE PRODUCTS

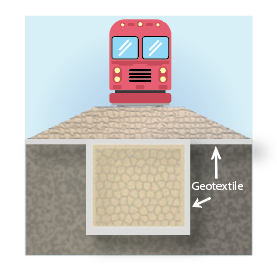

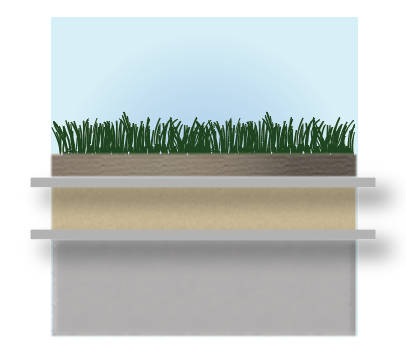

Geo-textile

DIRD Felt Ltd. non-woven needle punched geotextile ranges from 150 gsm to 1,000 gsm. Color options are gray, white and black and can be made using both PP and PET staple fibre.

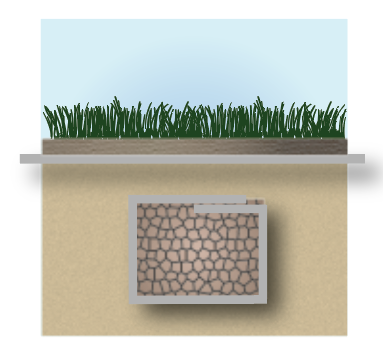

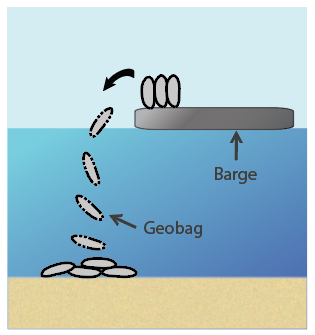

Geobag

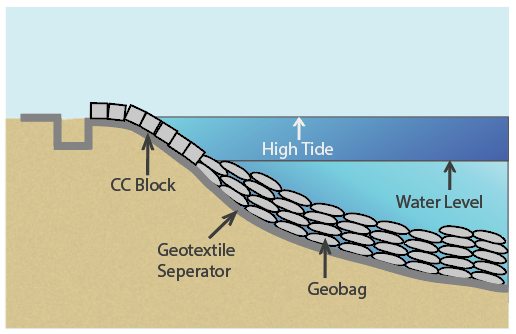

DFL geobags are stitched using Dird Felt geotextile. Stitching parameters and bag size are fully customizable to cater to client requirements.

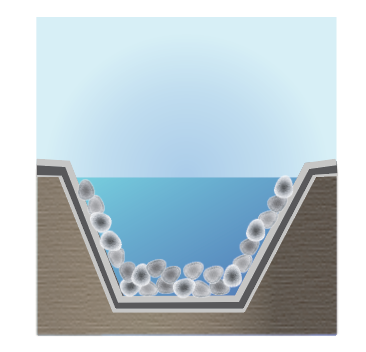

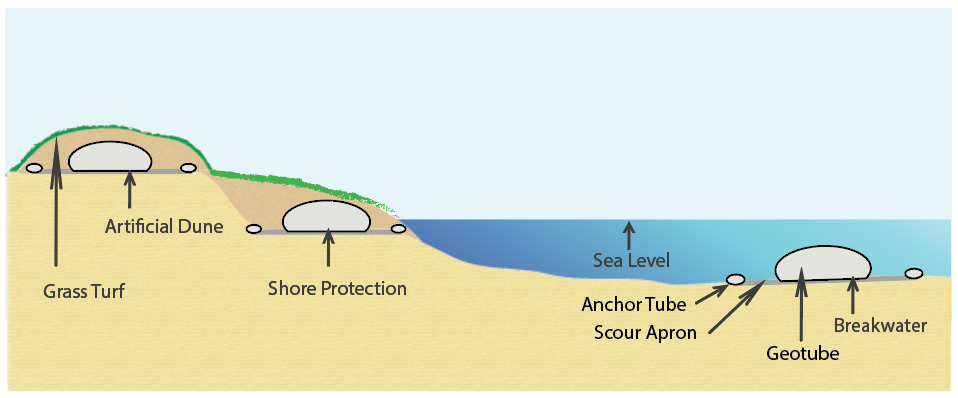

Geotube

DIRD Felt Ltd. geotubes are also made from our geotextiles. They are suitable for coastal and riverbank protection.

Geocontainer

DIRD Felt Ltd. geo containers are box-like containers made from non-woven geotextile. They are made-to-order to cater for special projects.

Specialized geotechnical engineering solutions

Dird is one of the few organizations in Bangladesh that has extensive experience in geotechnical engineering and provides specialized geotechnical engineering solutions. Dird Felt in association with Dird Engineering provides a one-stop solution including engineering design, material supply and execution.

The range of services are as follows:

- Soft soil stabilization

- Embankment construction

- Vertical wall with geosynthetics

- Supply and installation of PVD

- Riverbank and coastal erosion protection

- Slope protection

- In additional to non-woven geotextile supply, DFL is also the sole distributor of Huesker high strength/ reinforced geotextiles, woven geotubes, geogrids, geo membranes and clayliners.

Quality Assurance

ISO Certified

DIRD Felt Ltd. is ISO 9001 certified and maintains complete traceability of its manufactured products.

Currently, DIRD Felt Ltd. employs over 25 engineers who are directly involved in every step of the process, starting from production and quality control to design, marketing and implementation.

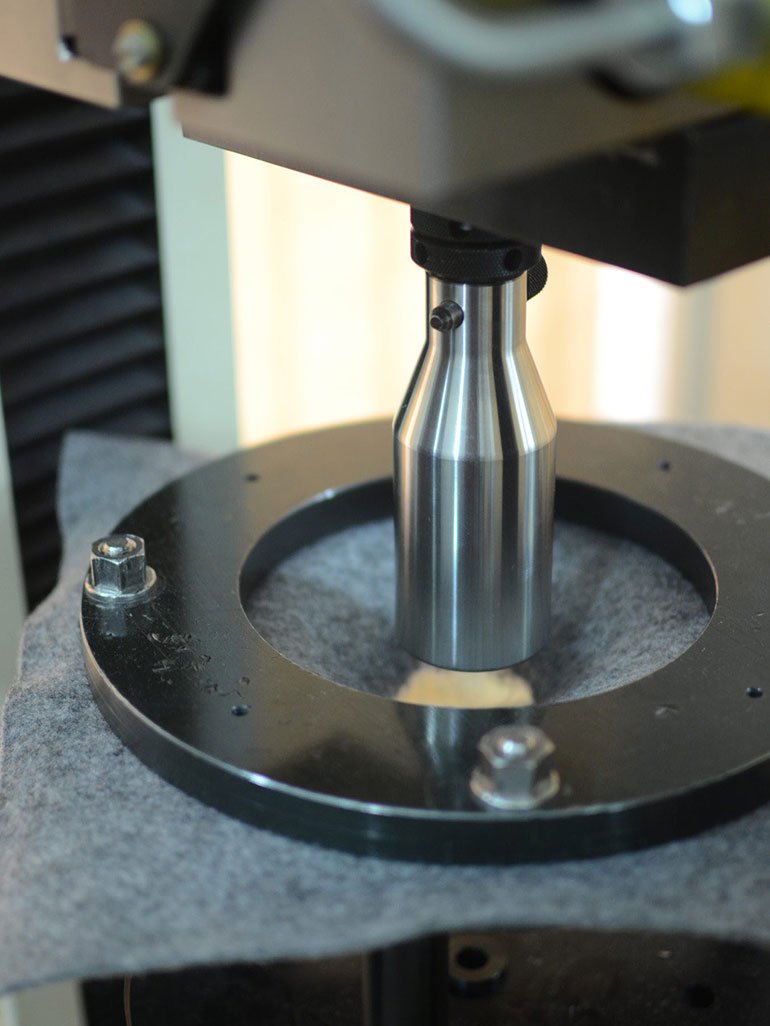

Geotextile Testing Lab

All of our products go through rigorous quality checks.To facilitate its strict quality system, we have our own in-house testing lab equipped with state-of-the-art testing machines to carry out all mechanical properties tests for geotextile.

Research & Development

We have a dedicated R&D team to innovate new techniques to improve its product quality and optimize its production systems.

Pet flakes and staple fibers

Vertical Integration

- DIRD Felt Ltd. manufactures both PET and PP staple fiber in-house.

- Our PP staple fiber is manufactured using virgin grade PP resin as raw material.

- DIRD Felt Ltd. recycles waste PET bottles to convert into PET flakes and uses it as the raw material for manufacturing PET staple fiber.

- Our recycling facility reduces our carbon footprint and helps in our sustainability goals.

Geotextile applications

MAJOR Customers

- Bangladesh Water Development Board (BWDB)

- Bangladesh Army

- Bangladesh Water Development Board (BWDB)

- Bangladesh Army

- Bangladesh Railway

- Bangladesh Bridge Authority (BBA)

- Bangladesh Roads and Highways Department (BRHD)

- Local Government Engineering Department (LGED)

- Bangladesh Power Development Board (BPDB)

- Bangladesh Inland Water Transport Authority (BIWTA)

- Bangladesh Navy

- Dhaka WASA

- Dhaka City Corporations

- Chittagong Development Authority

- RAJUK

- Local Private Entrepreneur

Certifications

Quality Management System